Laser Printer

High-speed. Reliable. Efficient

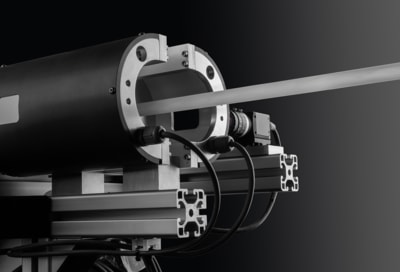

Laser Printers – High-Speed Marking, Engineered for Dripline

Metzer’s laser printing system is purpose-built for the unique demands of drip irrigation manufacturing. Developed specifically for integration into high-speed production lines, it delivers crisp, high-resolution marking of traceability data, product specs, or branding—without slowing down the line.

Unlike general-purpose printers, Metzer’s laser unit was designed with the material properties, line speed, and printing intervals of dripline extrusion in mind. It ensures consistent results even at speeds exceeding 300 meters per minute, on both thin and thick wall pipes.

Key benefits:

- High precision marking at high speed

- Contact-free, low-maintenance operation

- Easily changeable printing content through the production line interface

- Adapted for curved and flexible surfaces

- Compatible with multiple line configurations and control systems

Whether for internal quality control, product traceability, or brand visibility, Metzer’s laser printer guarantees durable, legible markings that last throughout the product’s lifecycle—no smearing, fading, or missed segments.

features

Control board| iMC5 Touch System

Galvo head| SG7210 (Fiber 1064 nm)

Laser source| Raycus RFL-P30QS, Air cooling

F-theta lens| 300×300 mm (F430 mm)

Machine body| 4th generation sheet metal body

Protective| Class-4 transparent windows

Fume extractor| YL-1001

Warning LED | Red/Yellow/Green + Beep

Senser | Door open switch sensor

Features

- Flexibility to produce all wall thicknesses and pipe diameters in range

- Can insert all Metzer flat dripper models by replacement of tooling sets (within a two hour set-up time)

- Customizable to customer’s preferred extruder brand

- Choice of extruder positioning; parallel or at 90ƕ to production-line

- Adaptable to customer’s drippers

- Optional configuration of dripper-spacing in groups of drippers (ideal for orchards and citrus)