Extrusion Cross-heads

Multi-layers innovative cross heads

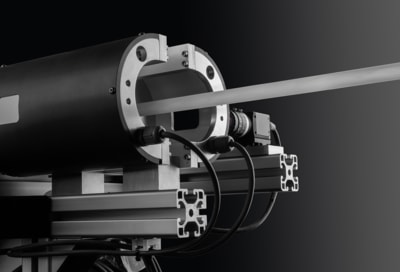

Extrusion Cross-Heads – Precision Forming for High-Quality Dripline

Metzer’s in-house engineered extrusion cross-heads are built to deliver consistent, high-precision pipe formation under the most demanding production conditions. Designed for thin and thick wall applications alike, our cross-heads ensure optimal material flow, uniform temperature distribution, and perfect pipe centering—essential for high-speed and high-quality dripline manufacturing.

Available in monolayer, dual-layer, and three-layer configurations (including ABA and ABC), Metzer cross-heads support a wide range of advanced applications such as:

- Color stripe embedding

- Metzer Rootguard® band integration

- Recycled and virgin material co-extrusion

Every unit is optimized for:

- Fast and easy tooling changes

- Symmetrical pressure distribution to prevent pipe rotation

- Stable operation at high line speeds

Built with durability and long-term performance in mind, our cross-heads combine precision machining, chemical treatment for wear resistance, and smart thermal control for repeatable, top-tier output.

Features

- Flexibility to produce all wall thicknesses and pipe diameters in range

- Can insert all Metzer flat dripper models by replacement of tooling sets (within a two hour set-up time)

- Customizable to customer’s preferred extruder brand

- Choice of extruder positioning; parallel or at 90ƕ to production-line

- Adaptable to customer’s drippers

- Optional configuration of dripper-spacing in groups of drippers (ideal for orchards and citrus)