Visual Inspection system – cylindrical Drippers

High-speed. Reliable. Efficient

Metzer’s visual inspection system is an advanced quality control solution designed to monitor and control the perforation accuracy of cylindrical drippers in drip irrigation pipe production. Positioned directly after the drilling unit, the system ensures that both outlet holes are present and correctly aligned with each emitter—maintaining consistency, minimizing waste, and enabling continuous correction.

Using two high-resolution cameras, the system captures images of both sides of each dripper immediately after perforation. Each hole is analyzed independently in real time to verify that it falls within the permitted drilling zone. If a hole is missing or out of position, an alarm is automatically triggered, and the relevant image is saved for operator review.

In addition to fault detection, the system calculates the precise position of each hole relative to the emitter center and sends the data back to the drill controller, forming a closed-loop correction system. When paired with Metzer’s servo drill, each side of the emitter is corrected independently. Compatibility with third-party perforators is also supported via fieldbus or digital I/O commands.

The last 20 alarm images per side are stored and accessible through a 19” LCD touchscreen interface, which also displays live visual feedback and enables quick parameter adjustments for various pipe sizes, wall thicknesses, and dripper types. Even while viewing saved alarms, the system continues to process and analyze new images without interruption—ensuring uninterrupted quality control at full line speed.

Key Features

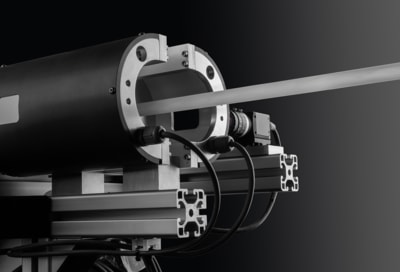

- Two high speed CCD digital smart cameras with precision lenses, positioned opposite each other on both sides of the pipe.

- Custom made sophisticated LED illumination system for crystal clear images.

- A small PLC accurately triggers each camera when the emitter is exactly in front of it. For optimal viewing adjustment, the emitter image on the screen may be shifted left or right with a couple of pushbuttons. A couple of digital outputs provide hole position correction pulses to third party perforators.

- Image analysis software runs on a dedicated high-speed vision controller.

- A 19” LCD screen provides the graphical user interface (GUI) and displays the captured images.

- Most of the electrical and electronic system is housed in a single electrical cabinet. The operating panel containing the LCD screen and the pushbuttons is mounted on top with a swivel joint and may be rotated to the desired viewing angle.

- System support frame made of modular aluminum profile.

- Built in remote support capability via the Internet.

- Airwipe and brush system for removal of drilling chips/cuttings.

Performance

Maximum Inspection Rate: 2 holes (1 on each side of the emitter): 700 drippers/min

4 holes (2 on each side of the dripper): 500 drippers/min

Diameter range: O.D. 12-20mm,

Wall Thickness range: 0.15-1.2 mm.

Maximum Line-Speed: 120 m/min

Features

- Flexibility to produce all wall thicknesses and pipe diameters in range

- Can insert all Metzer flat dripper models by replacement of tooling sets (within a two hour set-up time)

- Customizable to customer’s preferred extruder brand

- Choice of extruder positioning; parallel or at 90ƕ to production-line

- Adaptable to customer’s drippers

- Optional configuration of dripper-spacing in groups of drippers (ideal for orchards and citrus)